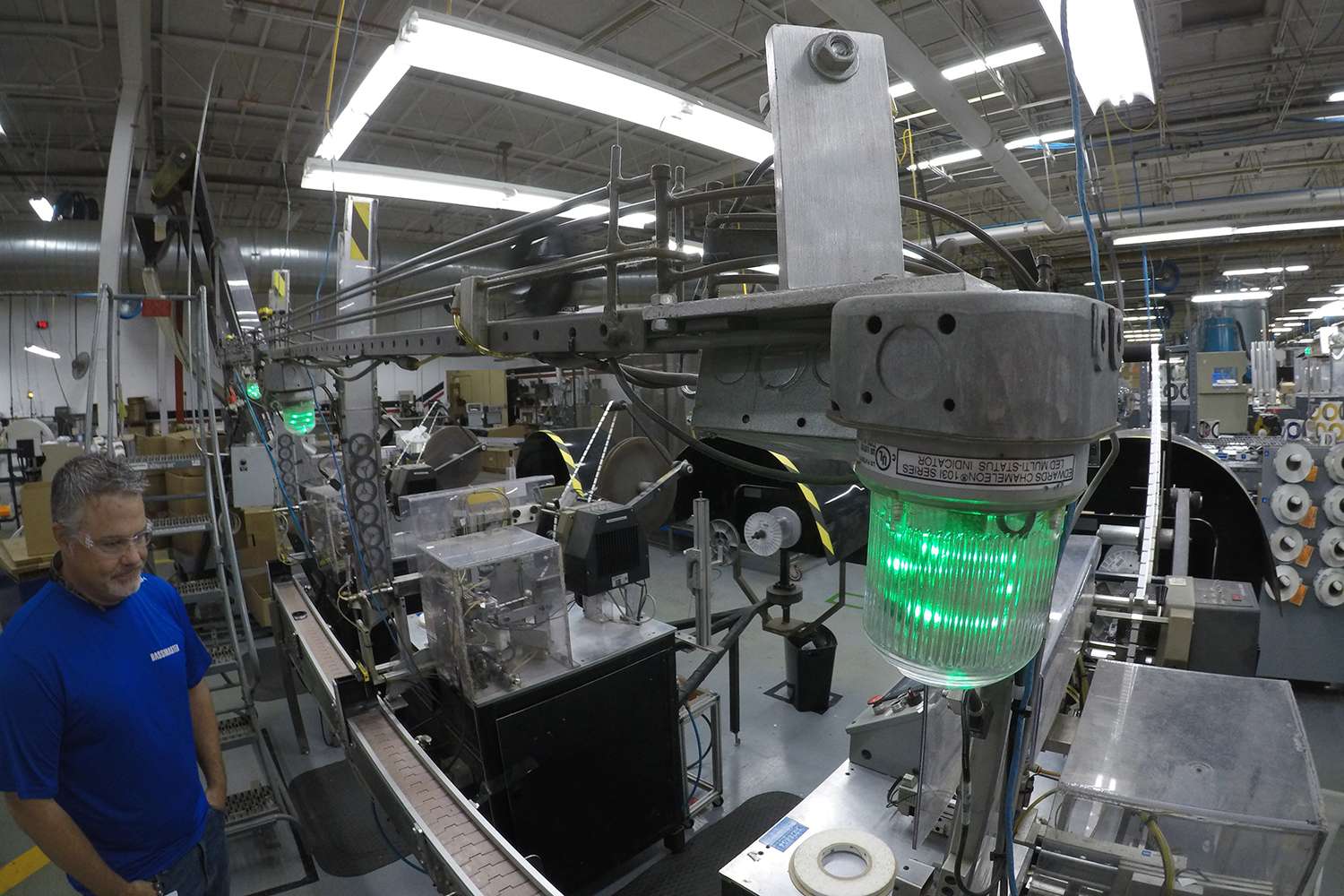

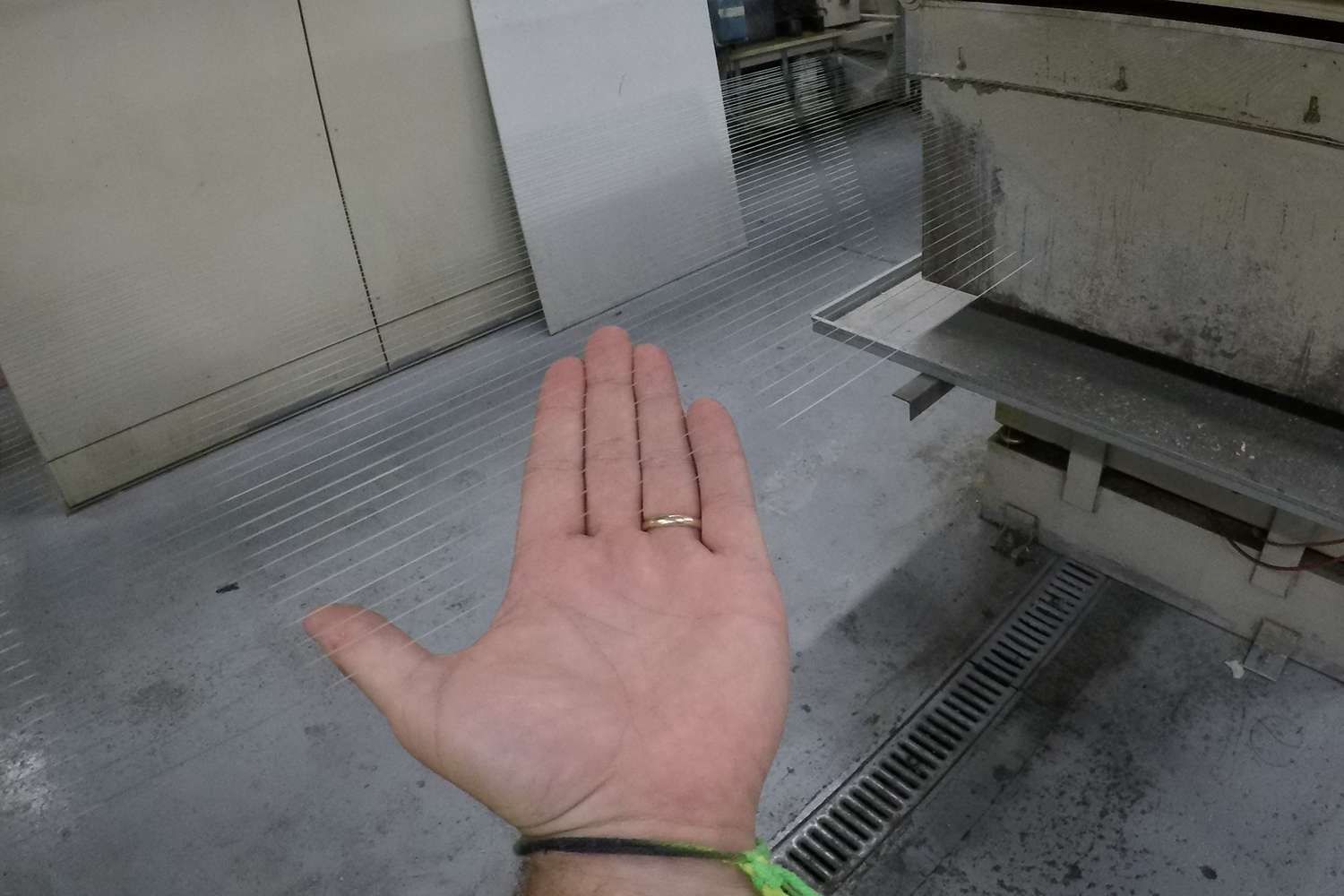

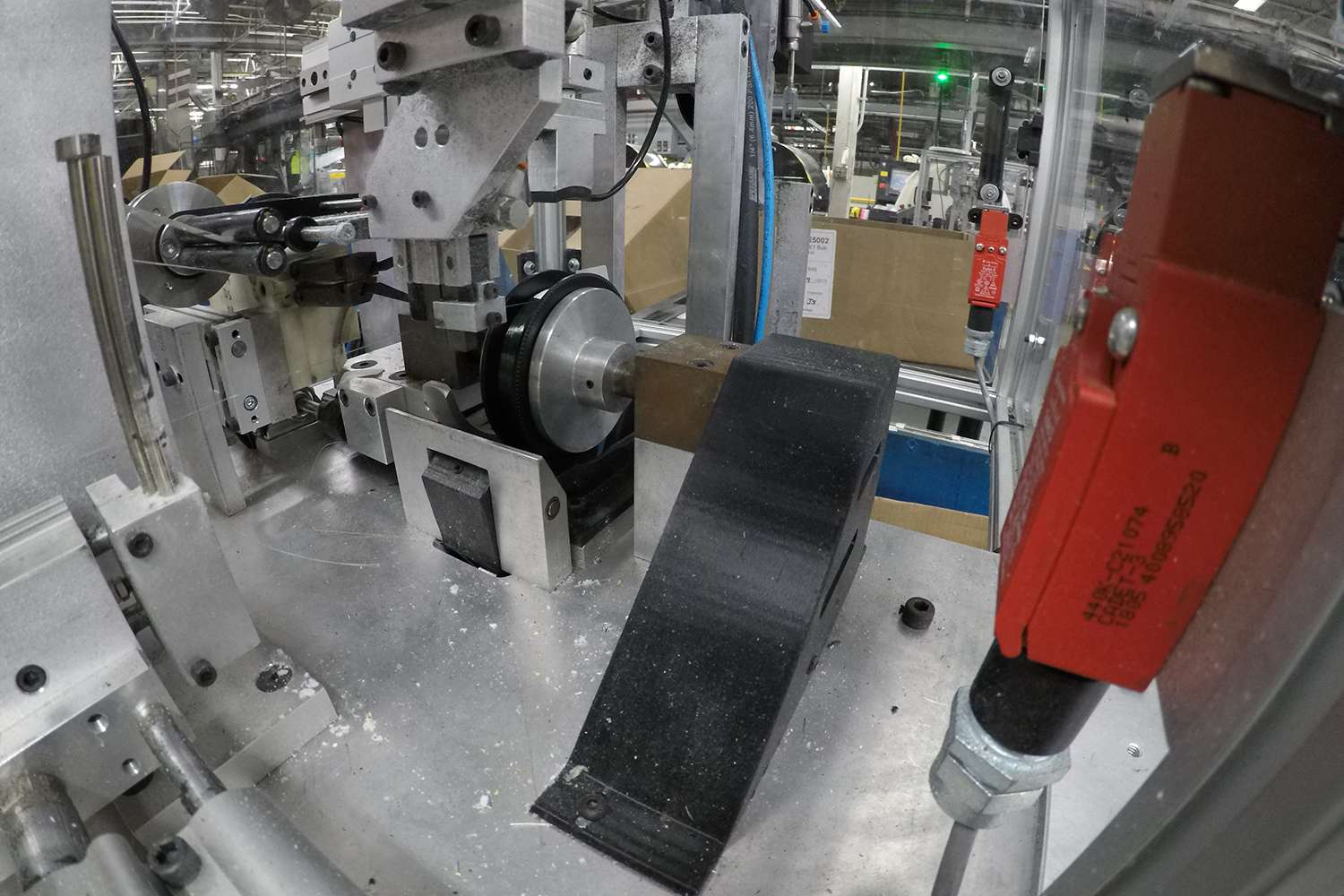

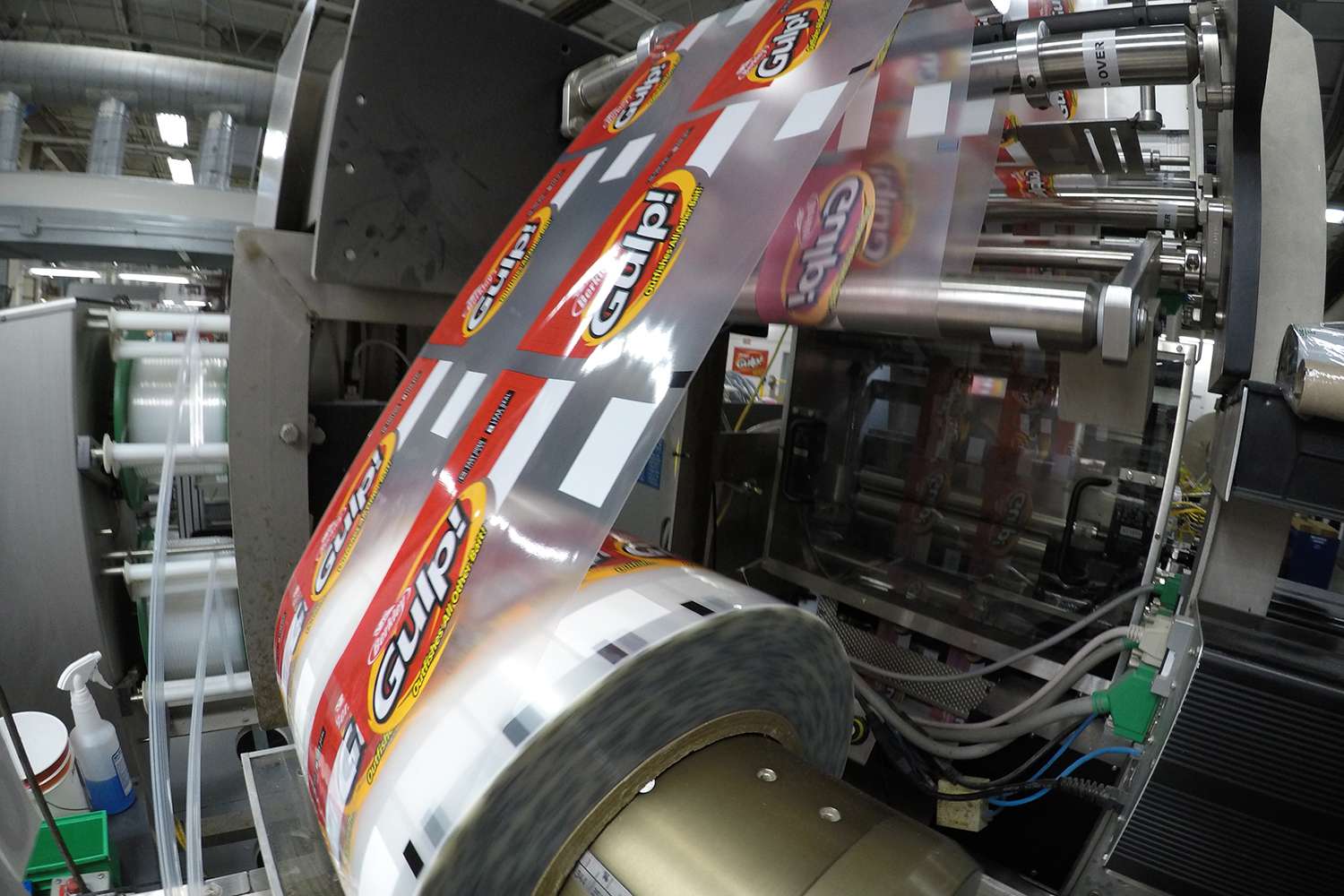

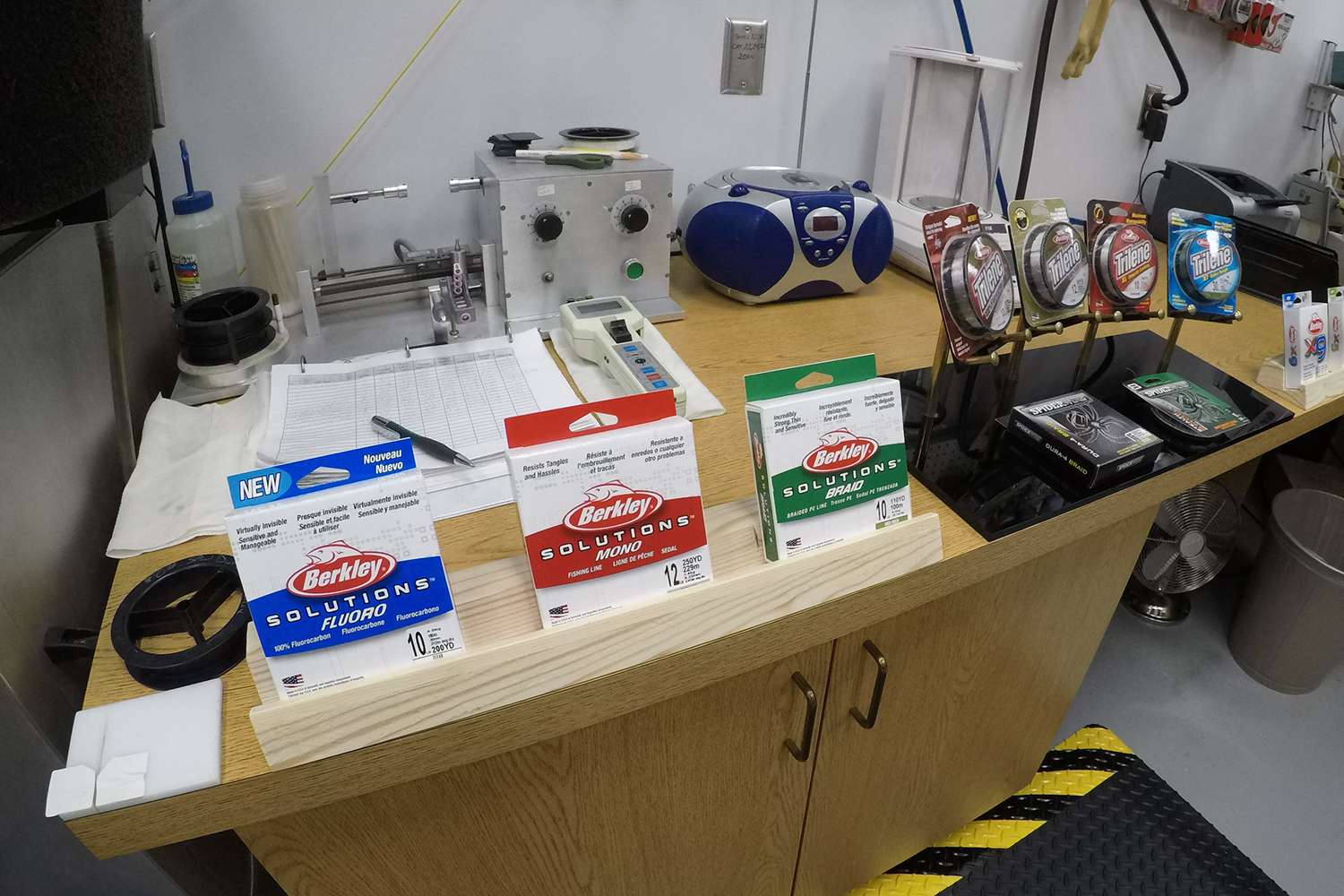

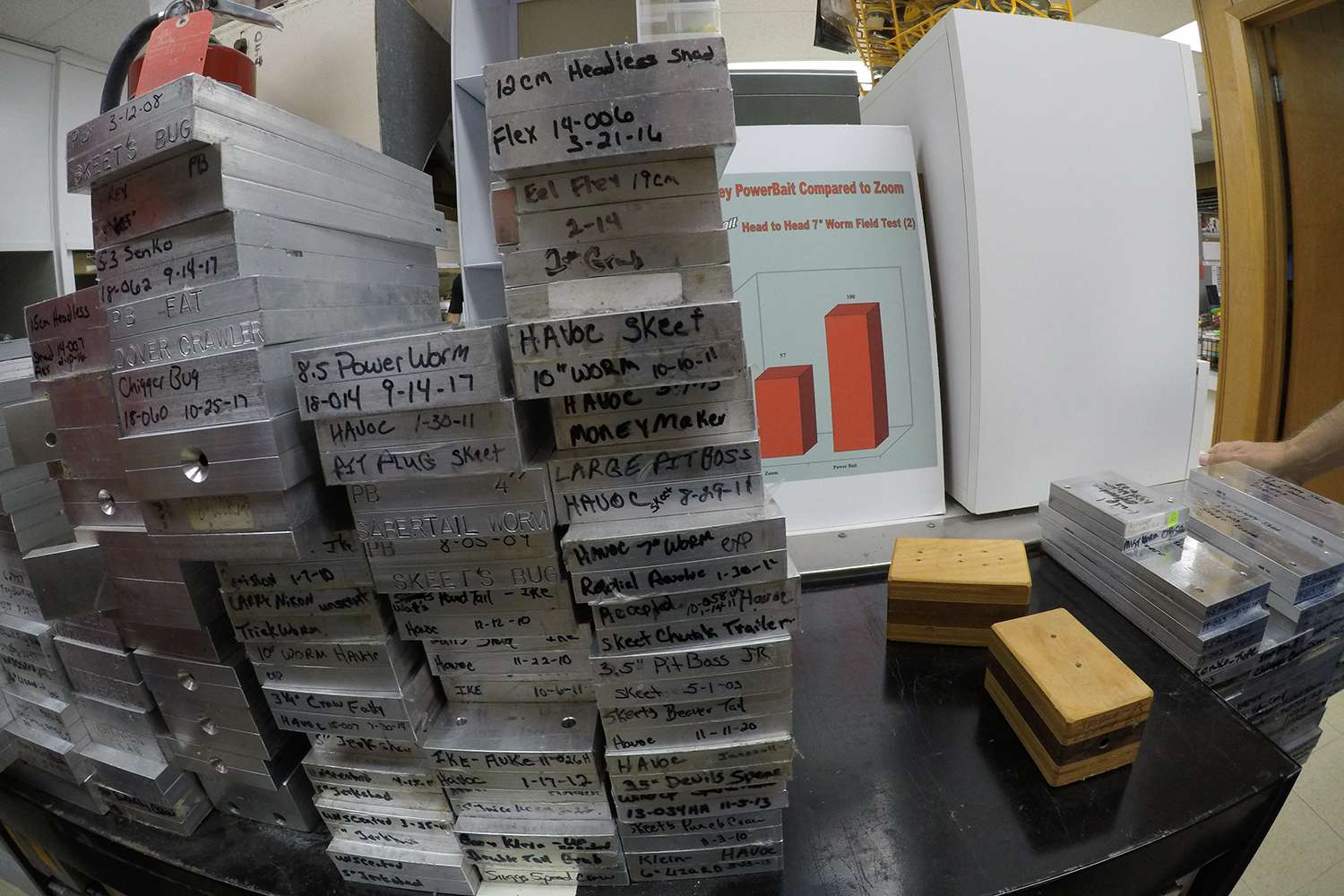

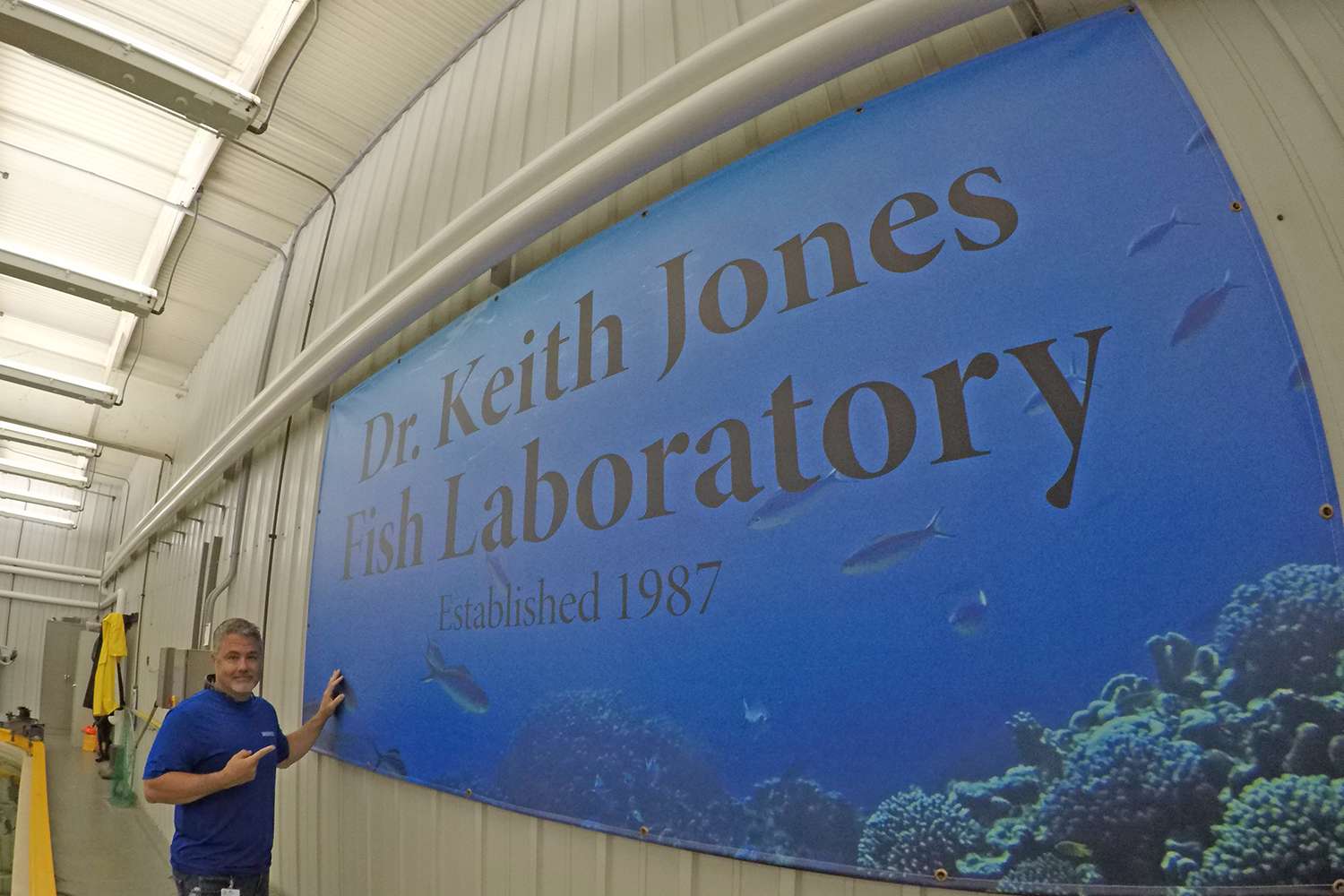

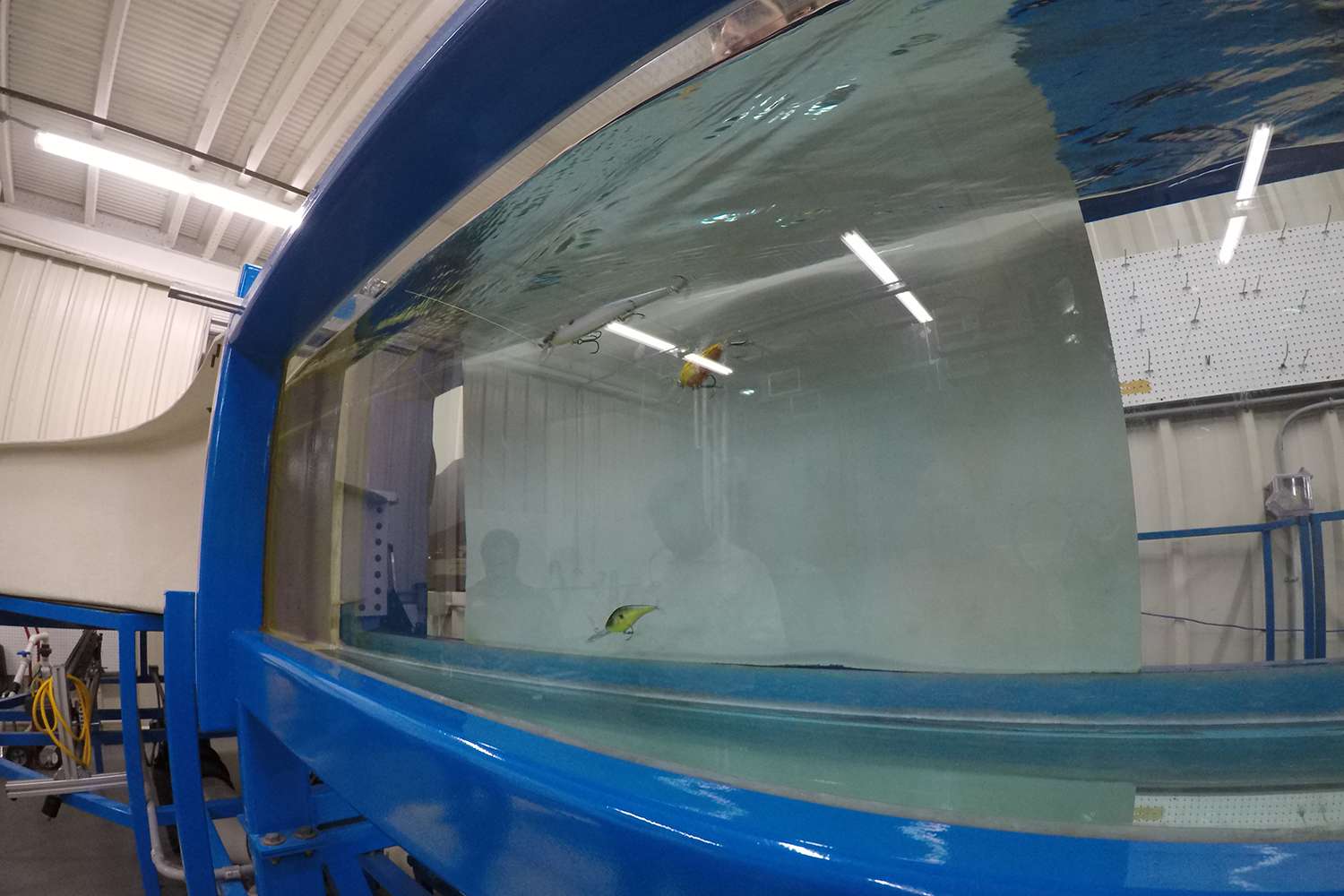

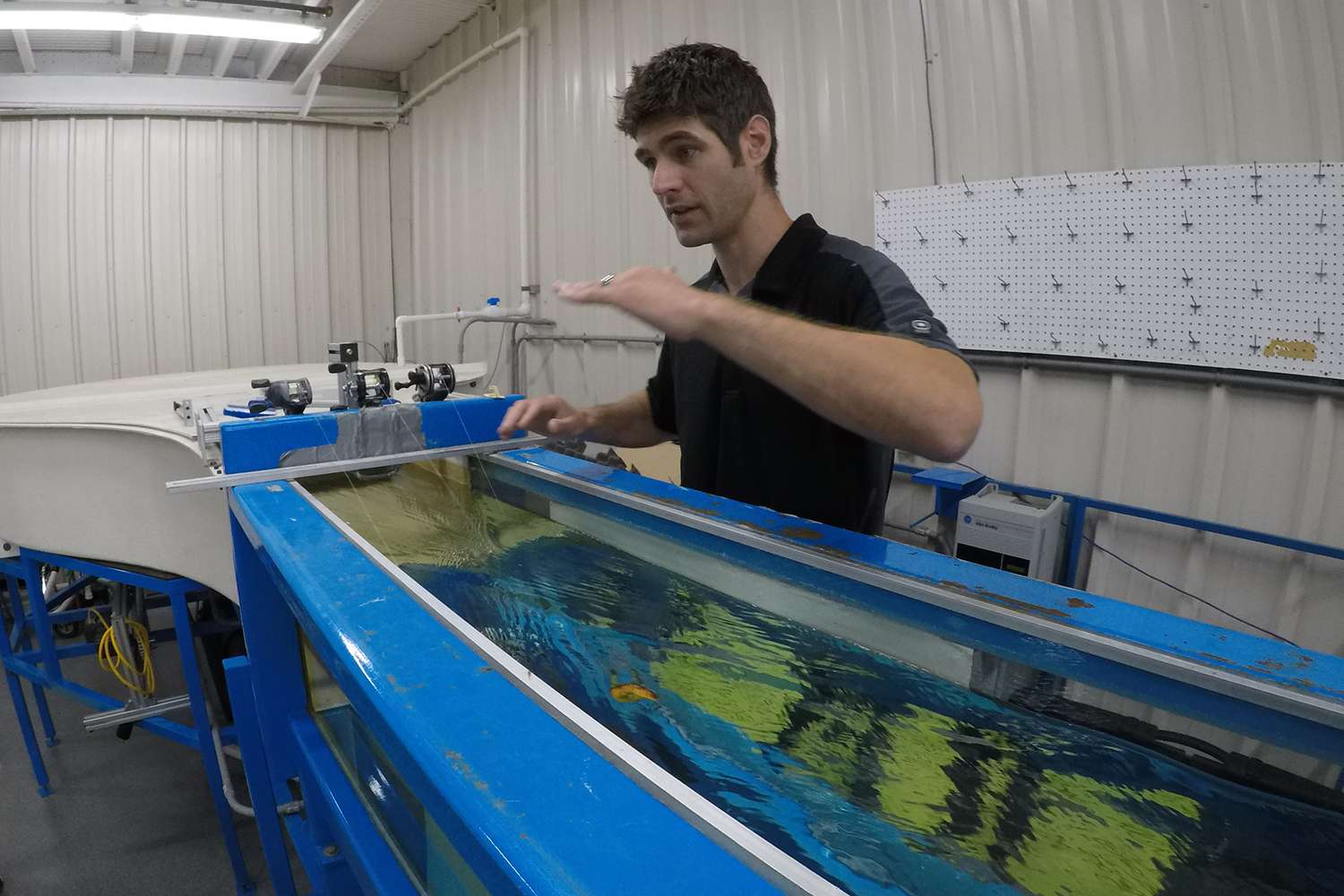

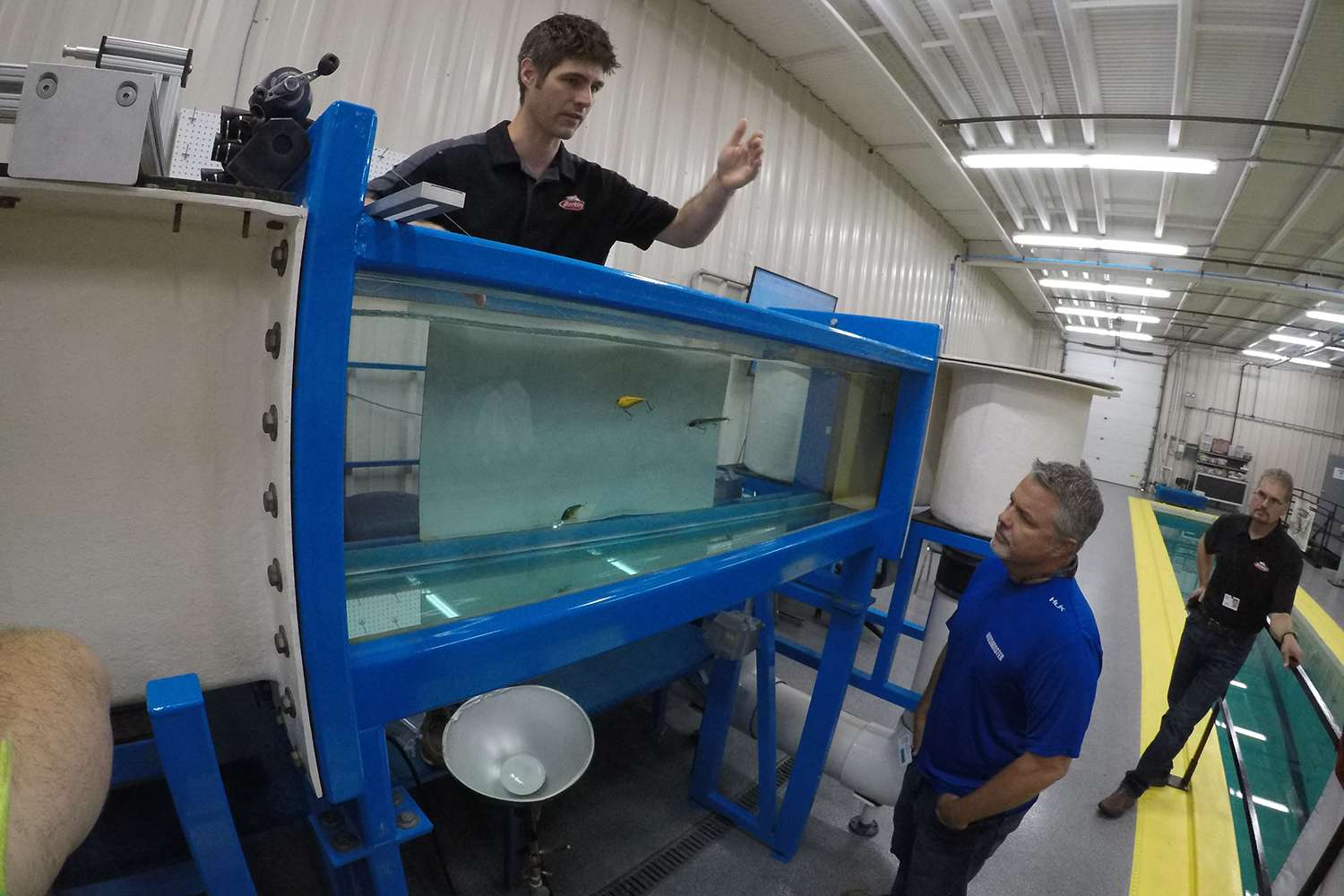

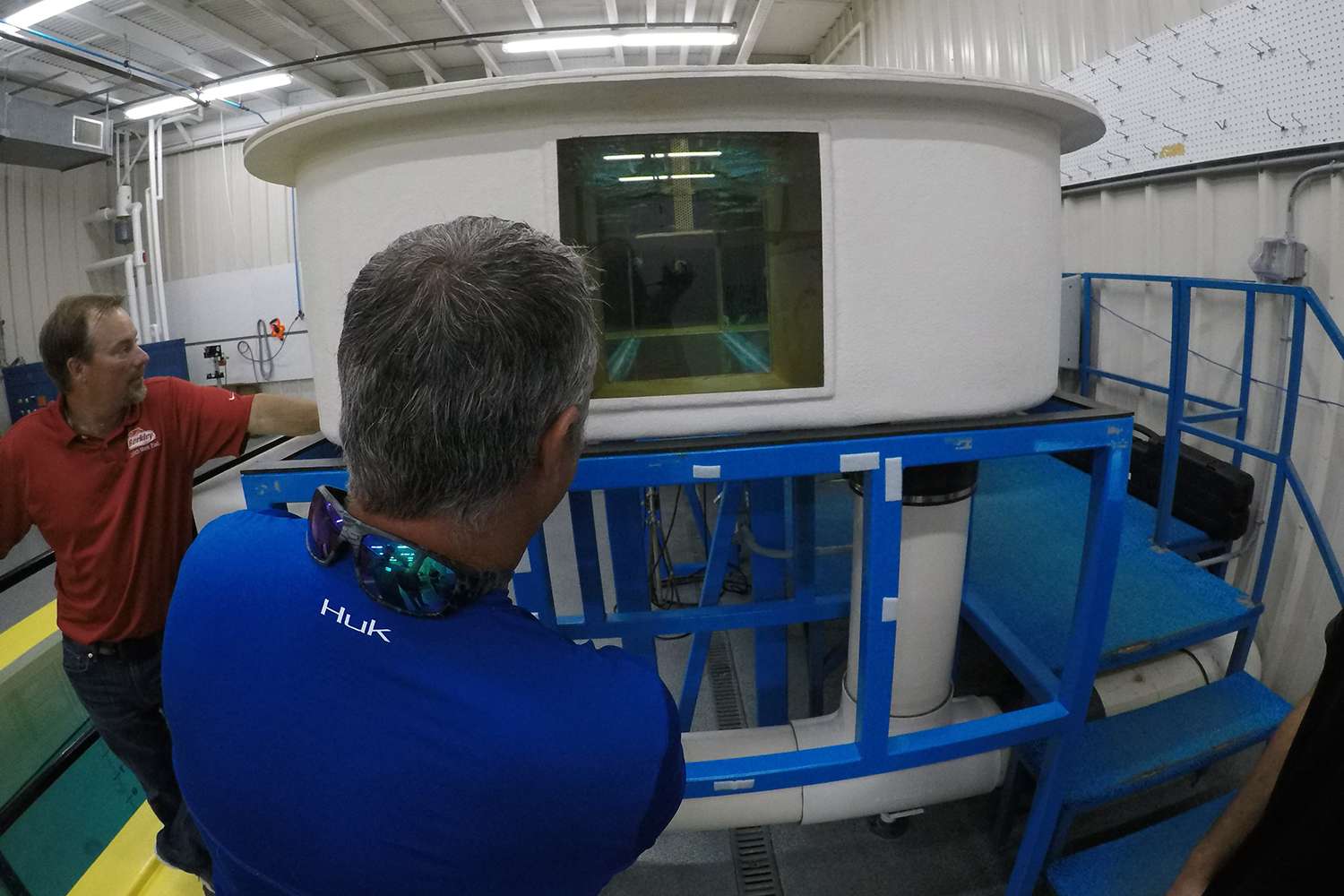

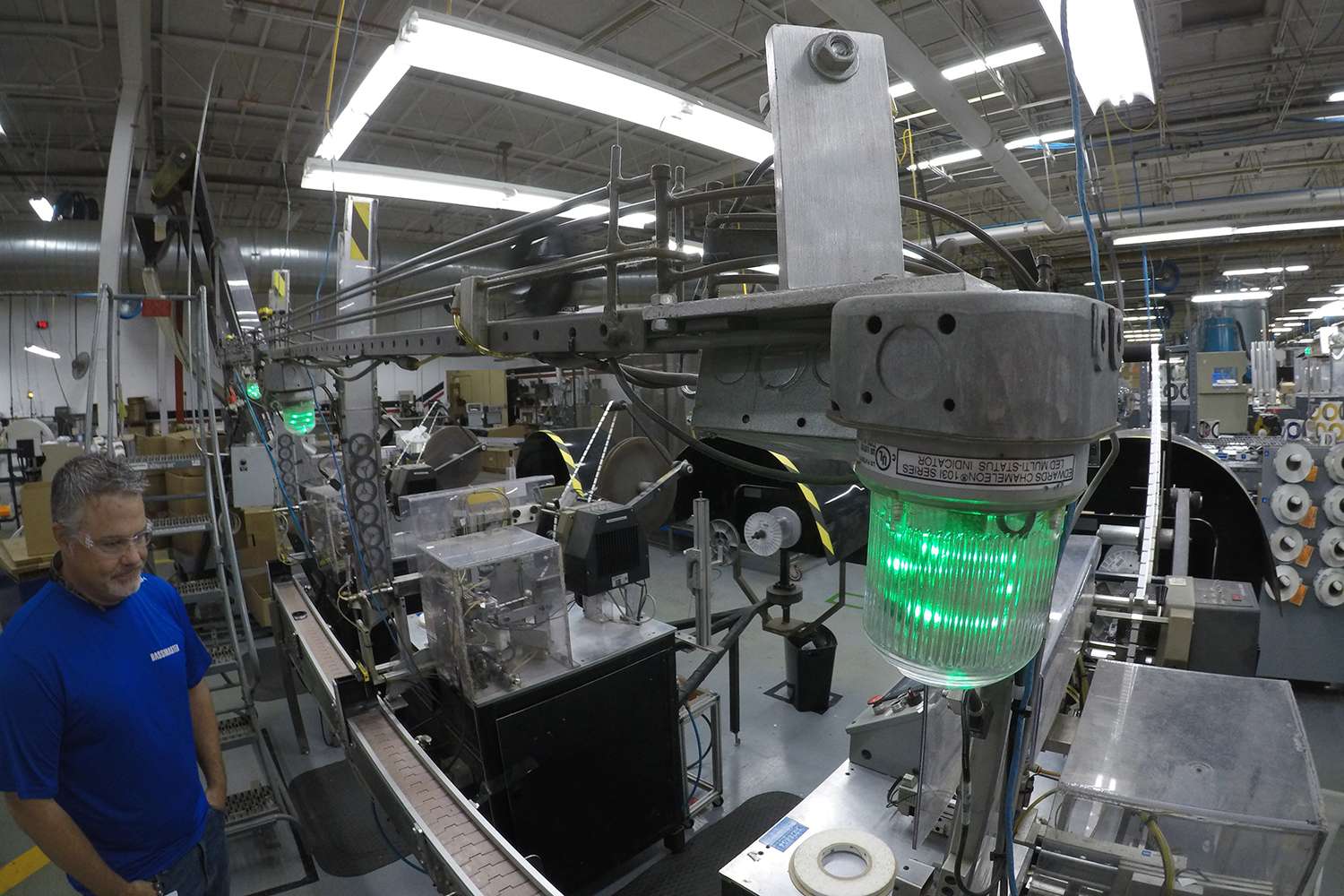

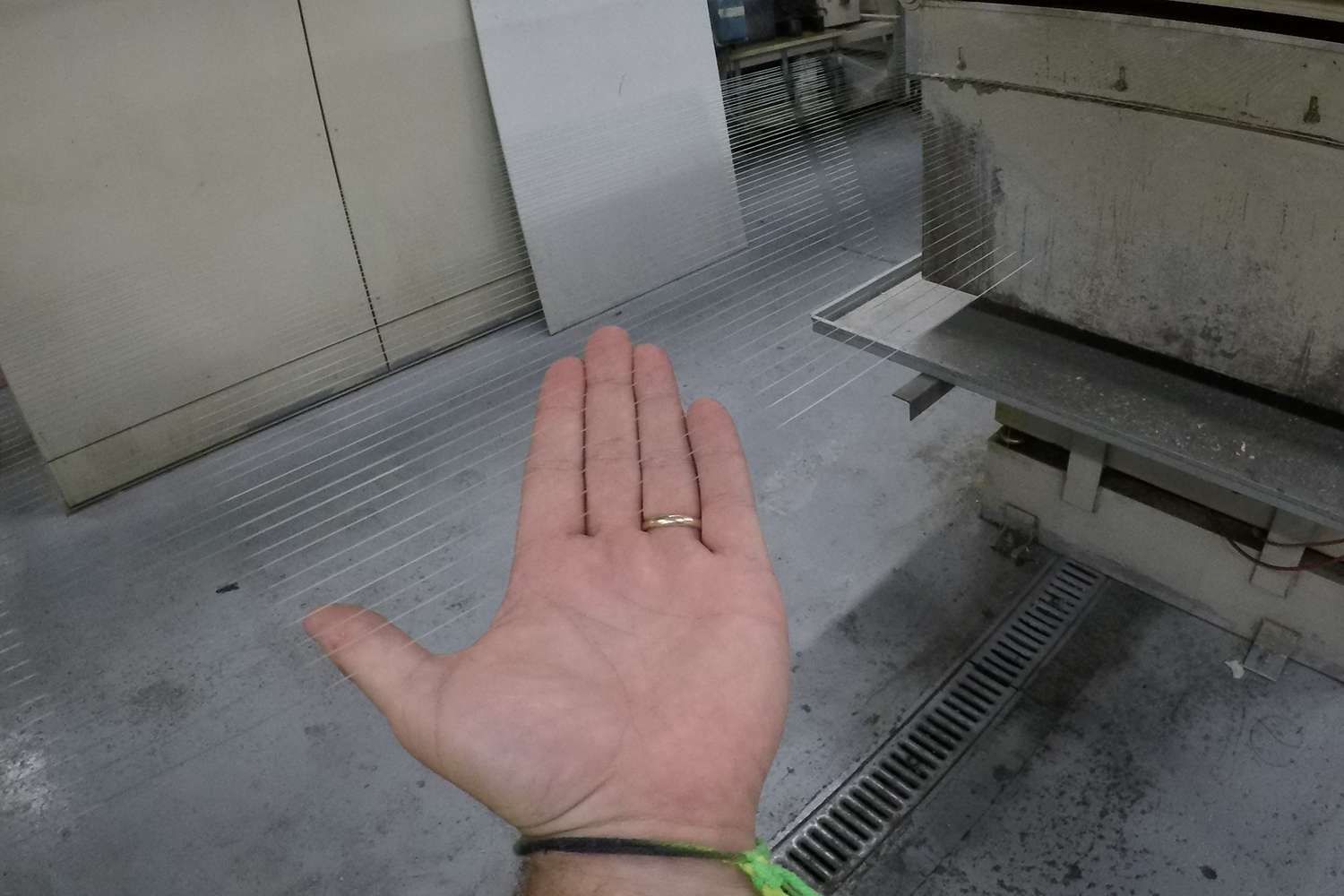

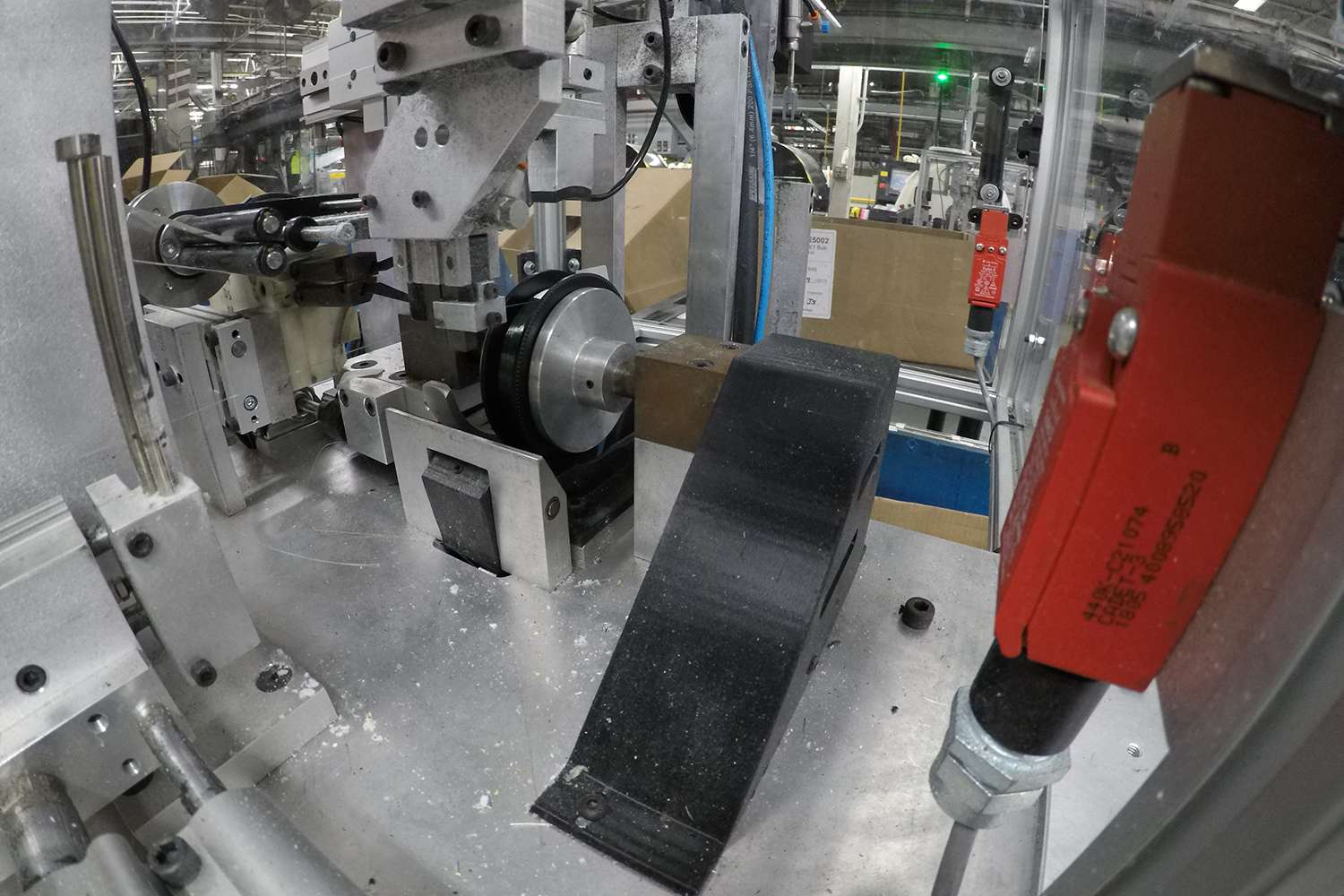

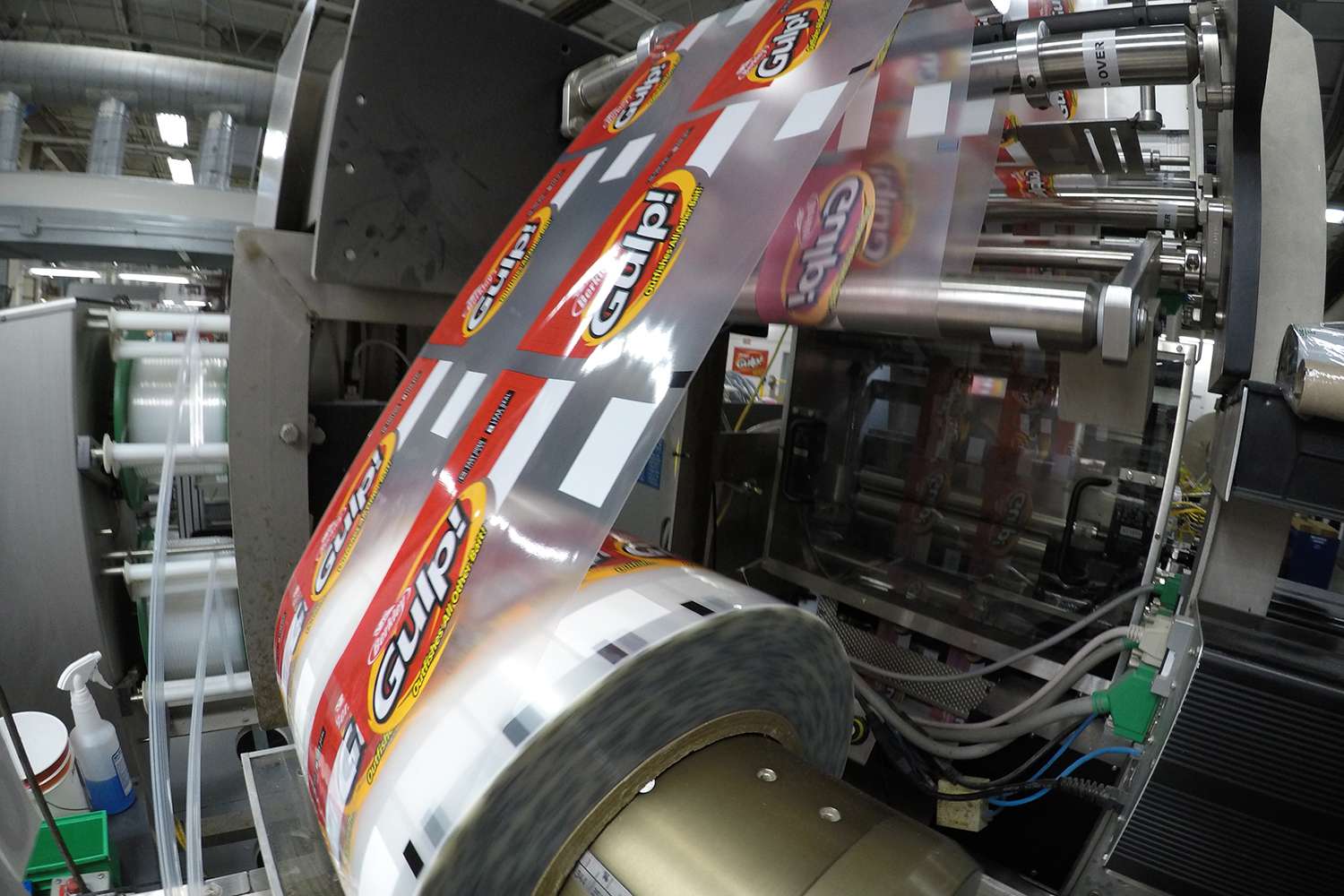

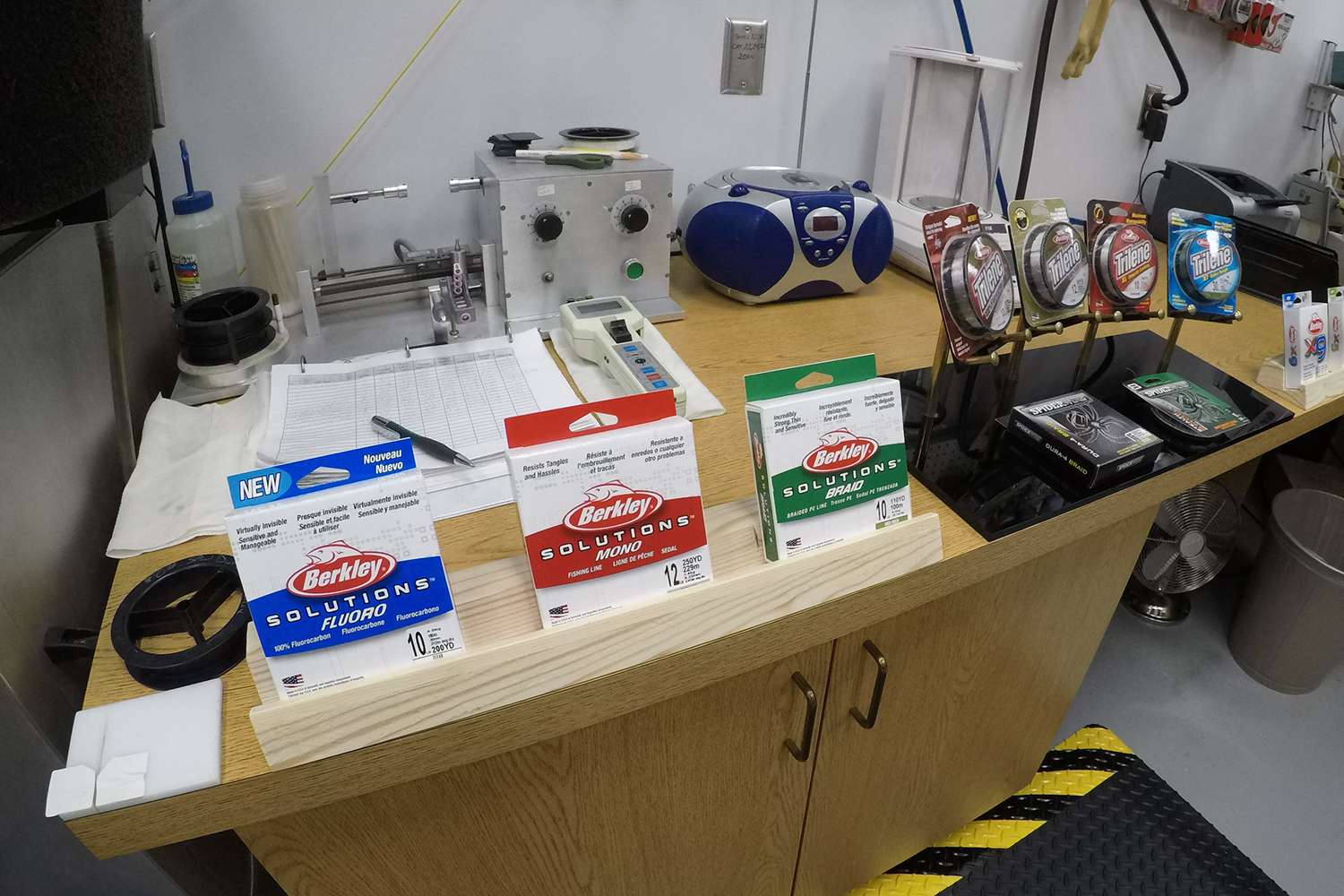

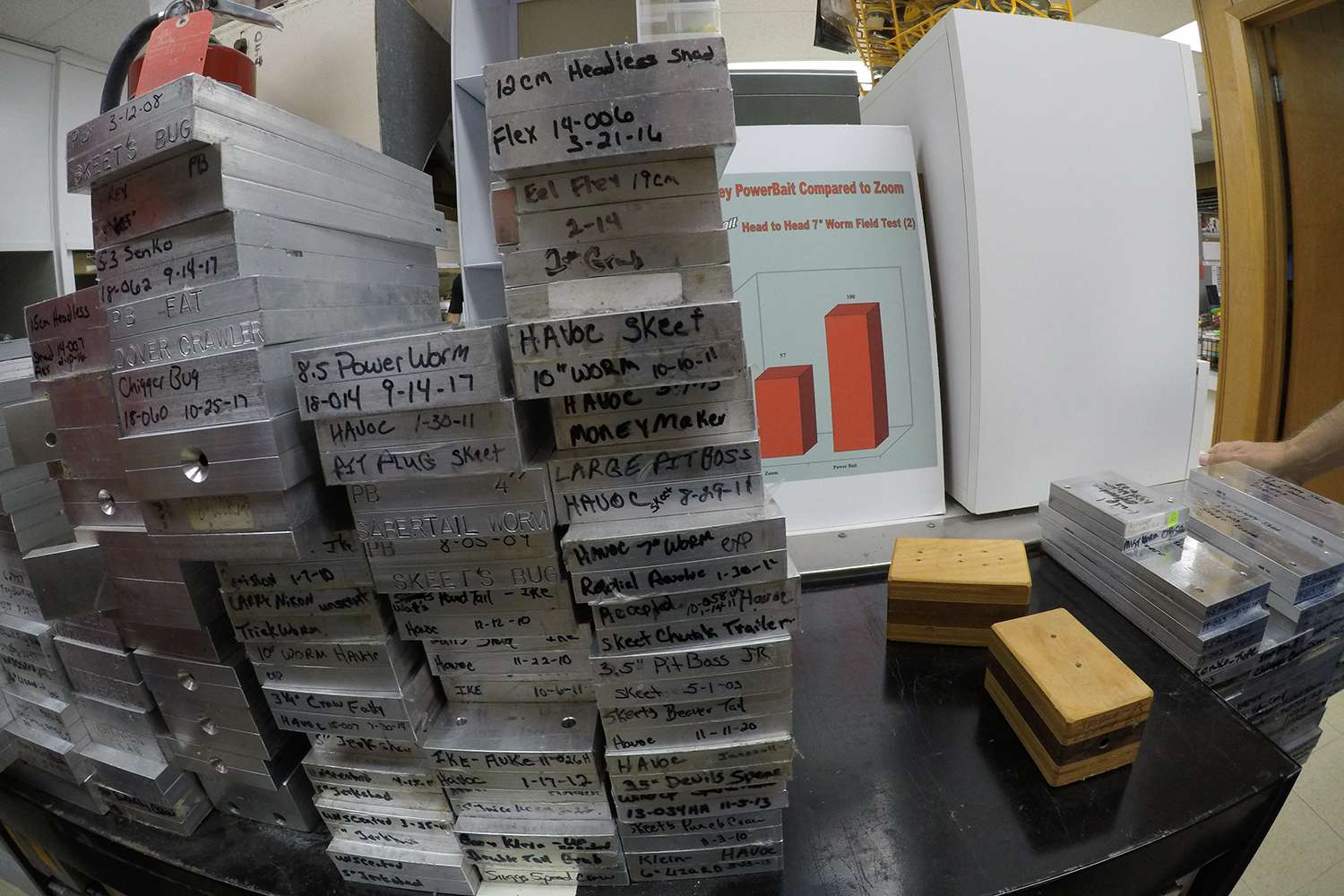

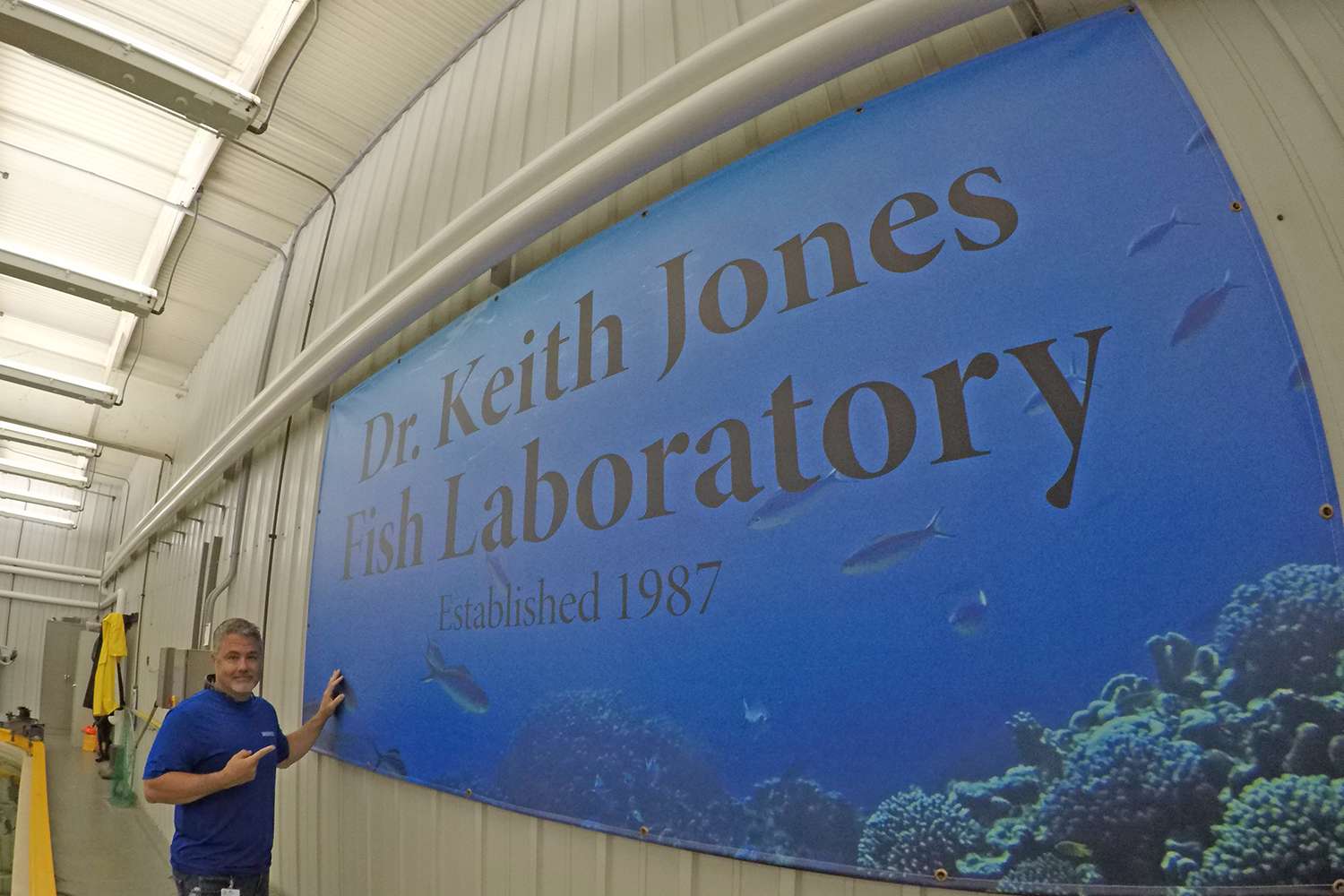

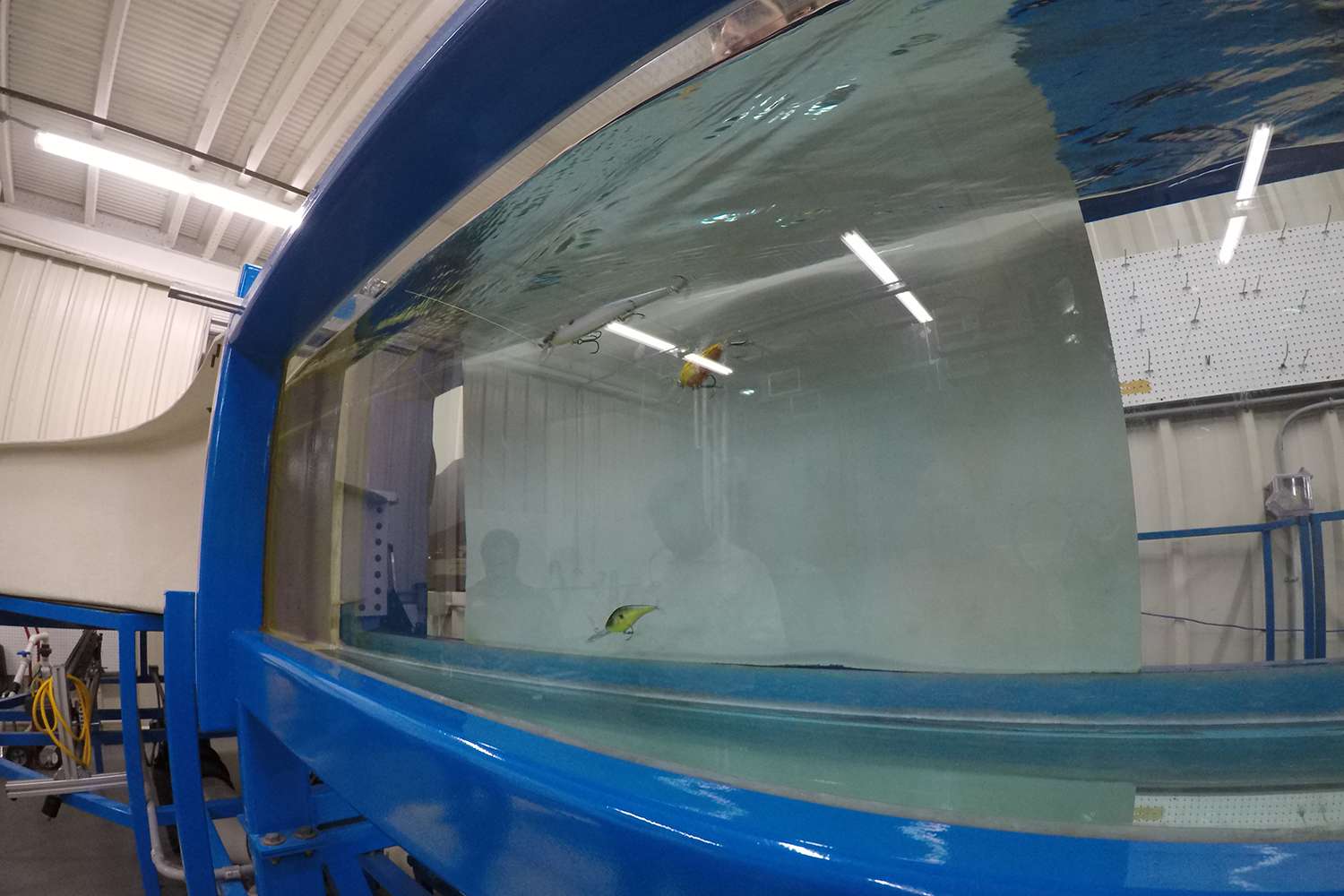

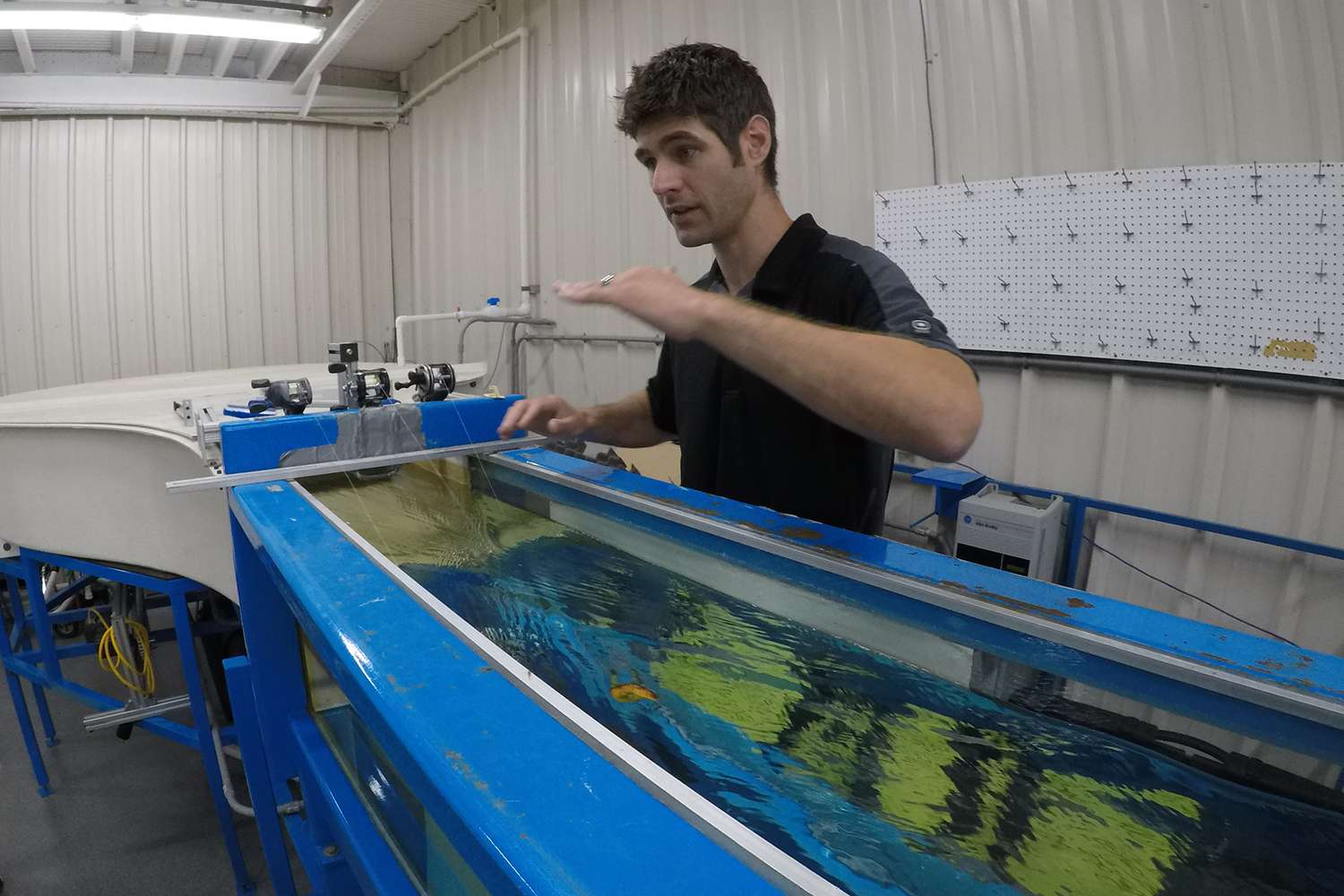

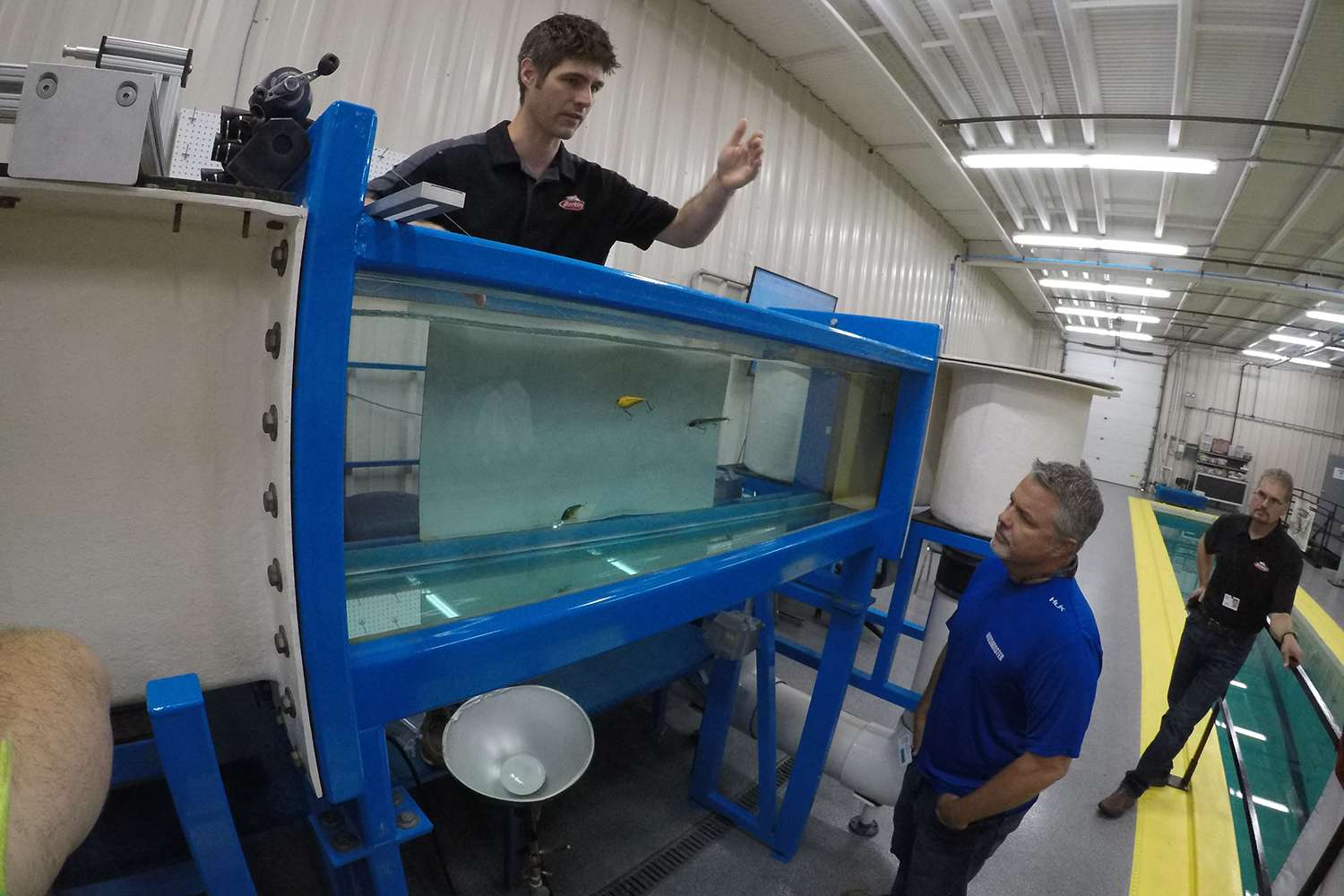

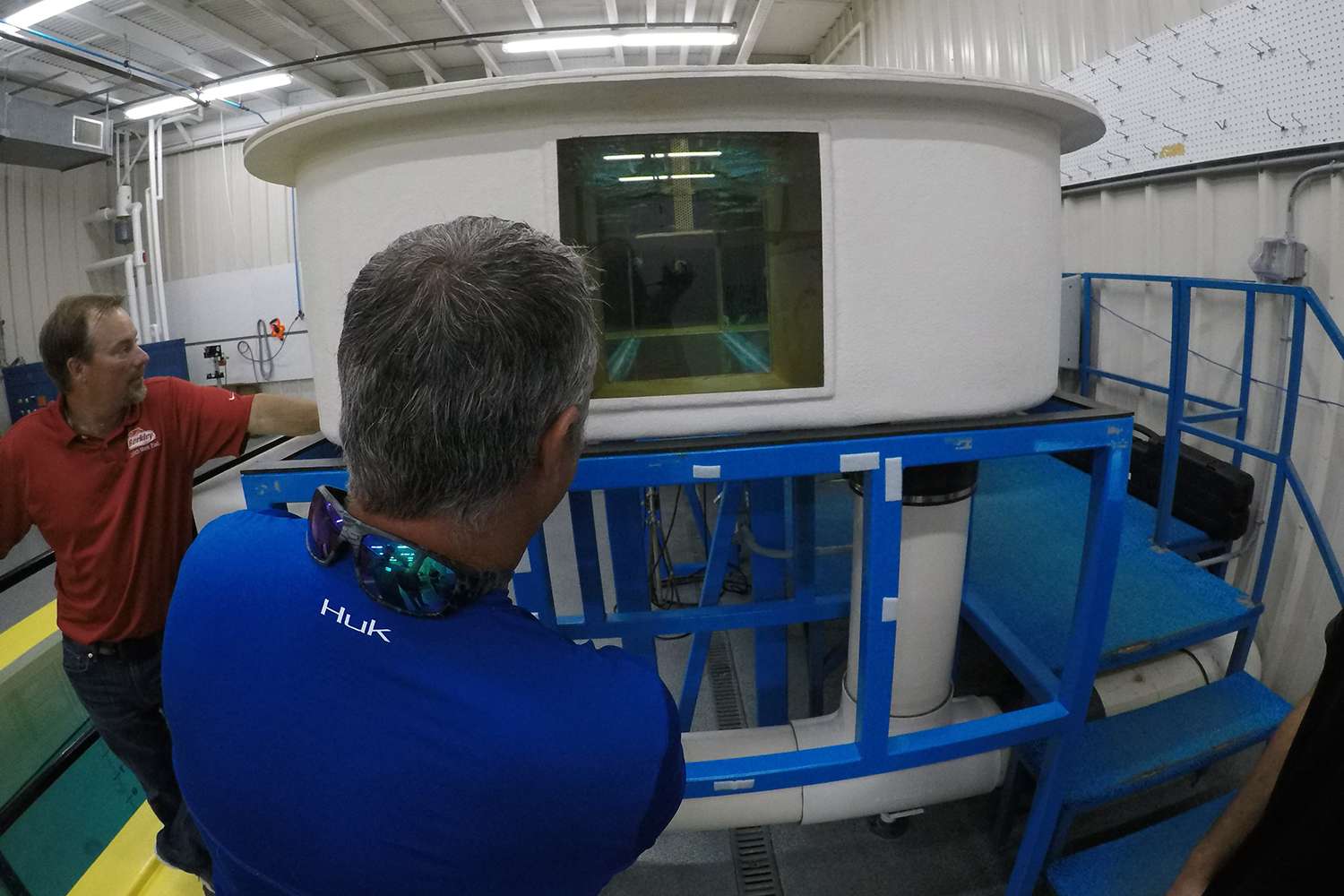

Talk about a very enjoyable tour of the world famous Berkley facility. What makes this whole process even better is the obvious level of passion these people exhibit about the sport we all love. Berkley has it going on!

Please enter your details.

We cannot find an active B.A.S.S. Membership for the information you have provided. Please renew your membership here.We cannot find an active B.A.S.S. Membership for the information you have provided. Please try again.Scheduled maintenance. We'll be back shortly. If you continue to have trouble please contact customer service at 877-BASS-USA.

Talk about a very enjoyable tour of the world famous Berkley facility. What makes this whole process even better is the obvious level of passion these people exhibit about the sport we all love. Berkley has it going on!